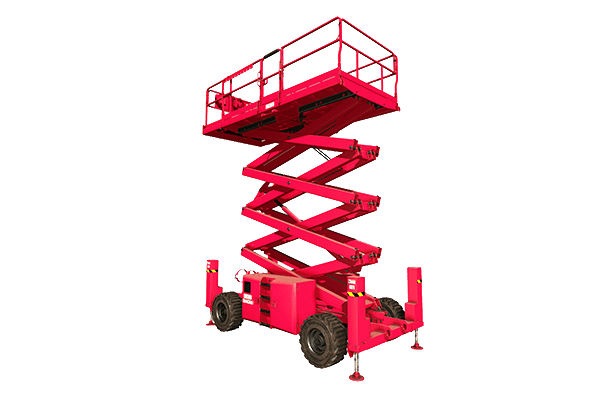

Okay, so the other day I had to deal with the scissor lift at work. It wasn’t going up smoothly, kind of jerky and making weird noises. Turns out, it was the rollers. Those little wheels that help the lift move up and down? Yeah, they were shot.

Figuring Out the Problem

First, I inspected the lift. I looked closely at the tracks and the rollers themselves. Some were chipped, others were totally seized up, and a couple were just plain missing! No wonder the thing sounded like a dying robot.

Getting Down to Business

Next, I gathered my tools. You know, the basics: wrenches, a socket set, some penetrating oil (that stuff is a lifesaver!), and of course, replacement rollers. I made sure I had the right size – wouldn’t want to go through all this trouble just to find out the new ones don’t fit.

- I sprayed the heck out of the old rollers with penetrating oil. Let it sit for a bit to really work its magic.

- Then, using my wrenches and socket set, I started removing the bolts holding the old rollers in place. Some were stubborn, but with a little muscle (and more penetrating oil), they finally came loose.

- Once the bolts were out, I pulled the old rollers off. Some practically fell apart in my hands – that’s how bad they were.

Putting It All Back Together

With the old rollers gone, it was time to install the new ones. I lined up each roller with its mounting bracket and inserted the bolts. Tightened everything down, making sure they were snug but not overly tight (you don’t want to crush the bearings).

Finally, I tested the lift. I raised it up and down a few times, listening for any weird noises and watching for any jerky movements. Smooth as butter! It was like a whole new machine.

It’s amazing what a difference a few little rollers can make. Definitely a satisfying fix, and the lift is back in action, ready for work.